Two roller-type CCR system

Z1810+ZZ270/12 Type Copper Rod Continuous Casting and Rolling Machine

The two roller-type CCR system is a production line for the continuous casting and rolling of low-oxygen bright copper rod of diameter 8mm. The material is qualified copper liquid from scrap copper and copper cathode.

1.Overview

Copper cathode or copper scrap→(Refining) Furnace →Launder→ Casting ladle→ Casting wheel →Front tractor →Rolling shear→ Straightener and Edge-planning→ Descaler→ Feeding unit → Continuous rolling machine →Reduction and cooling unit→ Waxing unit→ Back tractor → Coiler→ weighing and entering warehouse.

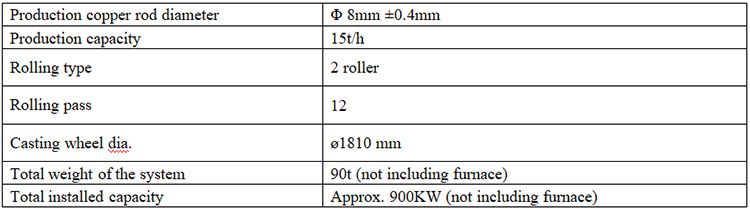

Major Technical data is given in the following table:

The rolling mill was replaced by one main motor from former roller with many motors, which reduced the investment cost for customers and facilitated installation and commissioning. The two-roller mill overcomes the critical defect of Y-type mill that emulsion and oil can not be separated. For two-roller rolling mill, the emulsion is only used 3-5%, which can reduce production costs. The rollers can be replaced within a few minutes. Y type rollers need a few hours. In dealing with plugging accident, also only a few minutes, but Y-type must replace the rolling stand. So two roller mill has longer life time, and with fewer spare parts. Adjust the rolling pass for per rolling stand need less than one minute. The total investment is much less than the Y-type. This is mainly shown in the production of higher efficiency.