LHD450/13T high-speed aluminum wire drawing machine

LHD450/13T high-speed aluminum wire drawing machine

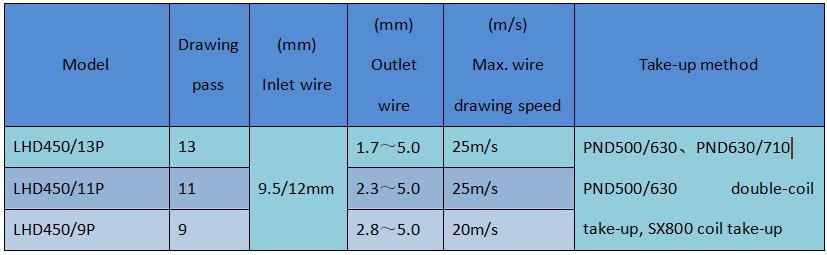

The machine is used to draw the Φ9.5/12mm aluminum rod to Φ1.7~Φ5.0mm single aluminum wire.

After the aluminum rod is drawn by the main wire drawing machine through the pay-off stand, it is finally taken up by the double-coil take-up machine or the coil take-up machine.

The machine adopts in-line sliding continuous wire drawing, and the drum is immersed in the wire drawing oil to draw aluminum wire. The main gear box and wire drawing are equipped with a set of lubrication and cooling circulating systems respectively.

The machine is fully mechatronic, adopts PLC programming, full-thread control of touch screen, and balanced matching of mechanical and electrical speed to realize rapid mold change, full-pneumatic automatic non-stop reel change and take-up. The production process is displayed on the human-machine interface on the color touch screen, and queried, adjusted and controlled by human-machine dialogue.

Main parameters:

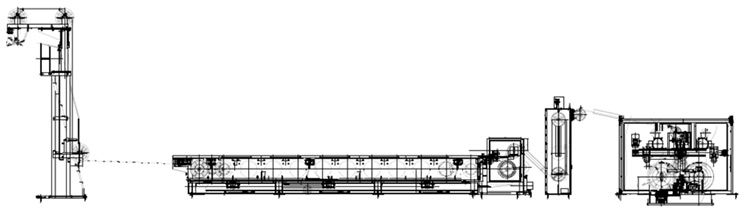

Equipment composition:

Pay-off stand - wire drawing mill - wire drawing oil cooling and lubrication system - wire storage tension control device - pneumatic double-disc automatic take-up device or SL800 coil take-up machine - PLC electrical control system - Wire pointing and stringing-up machine