LHD450/13T high-speed copper wire drawing machine (continuous annealing)

LHD450/13T high-speed copper wire drawing machine (continuous annealing)

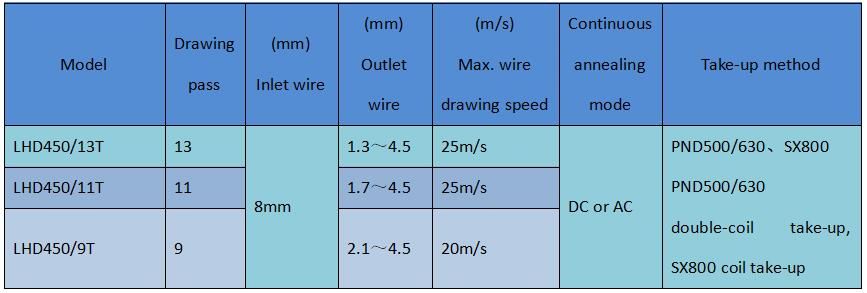

The machine is used to draw the Φ8mm copper rod to Φ 1.3~ Φ 4.5mm single copper wire.

After the copper rod is drawn by the pay-off stand into the main wire drawing mill, it is directly subject to continuous annealing and softening, and finally it is taken up by the double-coil take-up machine or the coil take-up machine.

The machine adopts in-line sliding continuous wire drawing, and the drum is immersed in the wire drawing emulsion to draw copper wire. The main gear box, wire drawing and annealing device are equipped with one set of lubrication and cooling circulation systems respectively.

The machine is fully mechatronic, adopts PLC programming, full-thread control of touch screen, and balanced matching of mechanical and electrical speed to realize rapid mold change, full-pneumatic automatic non-stop reel change and take-up. The production process is displayed on the human-machine interface on the color touch screen, and queried, adjusted and controlled by human-machine dialogue.

Main parameters:

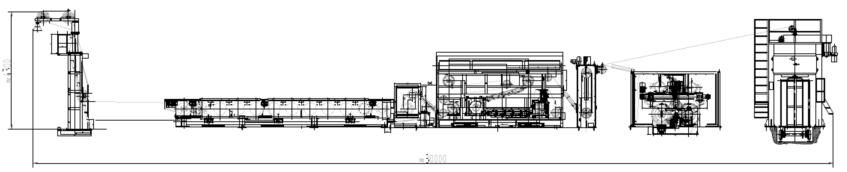

Equipment composition:

Pay-off stand - wire drawing mill - wire drawing emulsion cooling and lubrication system - wire storage tension control device - annealing device - annealing emulsion cooling and lubrication system - steam generator - pneumatic double-disc automatic take-up device or SL800 coil take-up machine - PLC electrical control system - Wire pointing and stringing-up machine.